Limited use Wastewater

Download the Limited Use Wastewater Information as a PDF

Vault: This is a large tank that holds at least 1,250 gallons of wastewater. It needs to be sealed tightly to prevent leaks and should have a warning system to let you know when it's getting full so that it can be emptied.

Vaulted Privy: This is a smaller tank, at least 400 gallons, made of concrete, plastic, or fiberglass. It has an outhouse built on top for use as a bathroom.

Composting Toilet: This is a toilet that doesn't use water. It breaks down waste using natural processes to reduce it.

Portable Chemical Toilet: This is a temporary toilet that you usually see at construction sites or events. It's a self-contained unit that can be moved around easily.

Graywater - Wastewater generated from lavatory sinks, showers, and laundry. Excludes wastewater from kitchen sinks and toilets.

What is a limited use wastewater system?

Limited use wastewater systems include vaults, vaulted privies, composting or incinerating toilets, and portable chemical toilets. These systems are designed for properties that produce very little wastewater or for properties that can’t fit a full on-site wastewater treatment system (OWTS) with a soil treatment area.

Dwellings built as cabins without plumbing and hauling or hand carrying their primary source of water, RVs used on properties seasonally, and semi-permanent campsites are the primary users of limited use wastewater systems.

When can a limited use wastewater system be used?

These systems are only allowed for seasonal or short-term use homes, properties that can’t have a full onsite wastewater treatment system, areas where a full system can’t be installed, or when water is hauled or carried by hand.

Maintaining these systems can be expensive because vaults or holding tanks need to be pumped out often. Limited use wastewater systems are not allowed on properties that are or could be used for full-time living, especially if the water comes from a well or public supply, unless a full onsite wastewater system isn’t possible or is prohibited.

Can a vault be installed for a cabin or seasonal dwelling?

A vault, vaulted privy, or composting toilet can be used if the building is considered a cabin under the Larimer County Land Use Code and Building Department rules, and it has no plumbing or the water is hauled or carried to the site. However, these systems are costly to maintain long-term, so a full wastewater system is recommended.

For homes, cabins with water from a well or public system, or cabins converted to homes, a full onsite wastewater system must be installed unless the property can’t support a full onsite system with a soil treatment area. Simply using the property seasonally or part-time is not enough to justify using a limited wastewater system.

Can graywater be disposed of on the ground?

No, graywater from showers, laundry, or sinks must be treated and disposed of as wastewater. Larimer County OWTS Regulations prohibit running pipes from RVs or homes directly to the ground.

Graywater contains bacteria, viruses, soaps and detergents, as well as other contaminants that can impact groundwater and surface water, potentially causing contamination to drinking water wells, lakes, and streams.

When is a permit required?

You need a permit before installing a limited use wastewater system. For new construction, you must plan how wastewater will be managed before getting a building permit. If the land is vacant, you must apply for a permit before installing a vault or vaulted privy.

Limited use wastewater systems during construction

Portable chemical toilets are only allowed on properties during the construction of a home or in emergency situations. Alternatively, you can install a vault, septic tank used as a vault, or a full septic system to serve temporary living quarters until construction is finished.

the pipe.

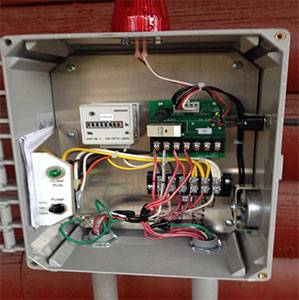

the pipe. Systems utilizing a pump to lift wastewater to a soil treatment area at a higher elevation or to provide pressure distribution must meet Section 43.9.I of the Larimer County On-Site Wastewater Treatment System Regulations. The following is a summary of the requirements:

Systems utilizing a pump to lift wastewater to a soil treatment area at a higher elevation or to provide pressure distribution must meet Section 43.9.I of the Larimer County On-Site Wastewater Treatment System Regulations. The following is a summary of the requirements:

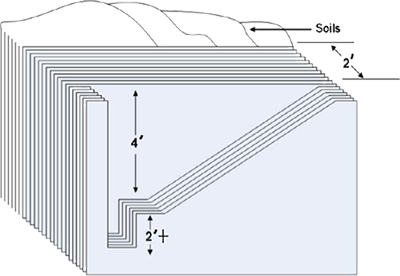

A soils report is required for all systems. It must include calculations for each component, a proposed layout of the soil treatment area, the tank depth, and the dimensions of trenches or beds. It should also detail the placement of distribution boxes, manifolds, or other parts of the system. For standard systems, this information can be part of the soils report or submitted separately.

A soils report is required for all systems. It must include calculations for each component, a proposed layout of the soil treatment area, the tank depth, and the dimensions of trenches or beds. It should also detail the placement of distribution boxes, manifolds, or other parts of the system. For standard systems, this information can be part of the soils report or submitted separately.